Press-Fit Connectors

As you might have guessed from their name, press-fit connectors are pressed through properly dimensioned plated-through holes on a printed circuit board (PCB). This technology is an alternative to the soldering method and offers a number of advantages over its more traditional counterpart. With press-fit connectors, you can eliminate a number of negative aspects that come along with soldering: thermal stress on the PCB, cold solder joints, shorts (caused by solder bridging), and the elimination of lead-free solder, which introduces its own set of problems. Press-fit connectors are also easily repaired, more environmentally friendly, and cost effective.

Press-Fit Connectors Defined

Press-fit technology allows manufacturers to avoid soldering when assembling PCB electronics. The press-fit connection is formed when a pin is pressed into a fitted, plated-through hole in a PCB.

There are different types of press-fit connectors, including those with solid pins (which don’t contort during insertion) and compliant pins (which compress or “comply” during insertion). Solid press-fit technology came first, but designers and manufacturers were concerned about the board damage caused by solid press-fit contacts. To combat the problem, compliant press-fit technology was developed. Today, compliant pins are generally preferred because they make less demands on the PCB, require less force during the insertion process, and produce more reliable results (with less damage). Both types are still currently used, but compliant technology tends to be more convenient and effective (and thus, more popular).

Positronic takes compliant press-fit technology one step further with its bi-spring power press-fit terminations. Compliant press-fit technology improved upon solid press-fit methods, but there is still a risk of damaging PCBs and backplanes due to the high force needed for proper insertion. Bi-spring power press-fit contacts reduce these insertion forces. They also add mounting screws for increased stability during shock and vibration environments (so the movement and stress caused by coupling, uncoupling, and shaky environments won’t transfer to the PCBs or backplanes). Plus, some bi-spring power press-fit connectors eliminate the need for costly press-in equipment.

When they’re used properly, press-fit terminations offer strong and reliable service, whether they’re employed in a benign application or a harsh one.

USES

Press-fit connectors are utilized in all sorts of applications, from data and communication to transportation and mechanics. Their dependable structure, functionality, efficiency, and numerous advantages over solderless technology make them quite popular. Companies often offer several termination options for their connectors, and press-fit technology usually snags a spot amongst those available options.

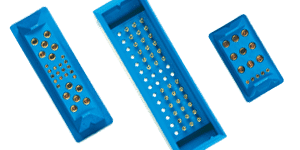

PRODUCTS

Positronic offers a number of different press-fit connectors that utilize compliant pin press-fit technology. For example, the Infinity High Power series reduces PCB and backplane damage by using a compliant press-fit system that implements low insertion and extraction forces. Infinity connectors have a high power density, large surface area contact system, and superior current carrying performance as well. Other products that offer press-fit termination styles include Standard Density D-Subminiature connectors, High Density D-Subminiature connectors, Combo-D connectors, and the Compact Power Connector family among others. All of these connectors offer a variety of termination styles as well as a large selection of accessories.

Find Your Sales Agent

We cannot locate a sales agent for the country you selected.

Please view our global locations and contact the facility that is most geographically near you.