PosiBlog

Automation Connectors: How Automation Is Changing the Outlook of the Industry

Did you know that almost every product you’ve touched today was likely the result of an automated manufacturing process? A milk carton, a tube of toothpaste, your car, your computer: all of these items are now typically produced through a largely automated system. We’re currently in the midst of a digital transformation, and many manufacturers are integrating automation into their operations as well. Yet despite the oversized role automation now plays in our world, most consumers rarely contemplate the technology required to manufacture products and ensure they arrive on time, maintain uniformity, and consistently meet high standards for quality. Within these systems, by providing connectivity and communication, industrial and automation connectors help facilitate the manufacture and delivery of goods. The market for automation connectors has surged, and Positronic is proud to be a part of this exciting trend.

How Automation Is Changing the Outlook of the Industry

The digital revolution is rapidly changing our society, our economy, and the future of connectivity products. Bolstered by artificial intelligence (AI) and machine learning (MI), automation is helping many companies make their systems more efficient and less reliant on employees. As an example of this, in 1964, AT&T was the most valuable company in the U.S. It employed about 758,600 people and was worth $267 billion in today’s dollars. Today, Google is worth $370 billion and yet it employs only about 55,000 employees (source).

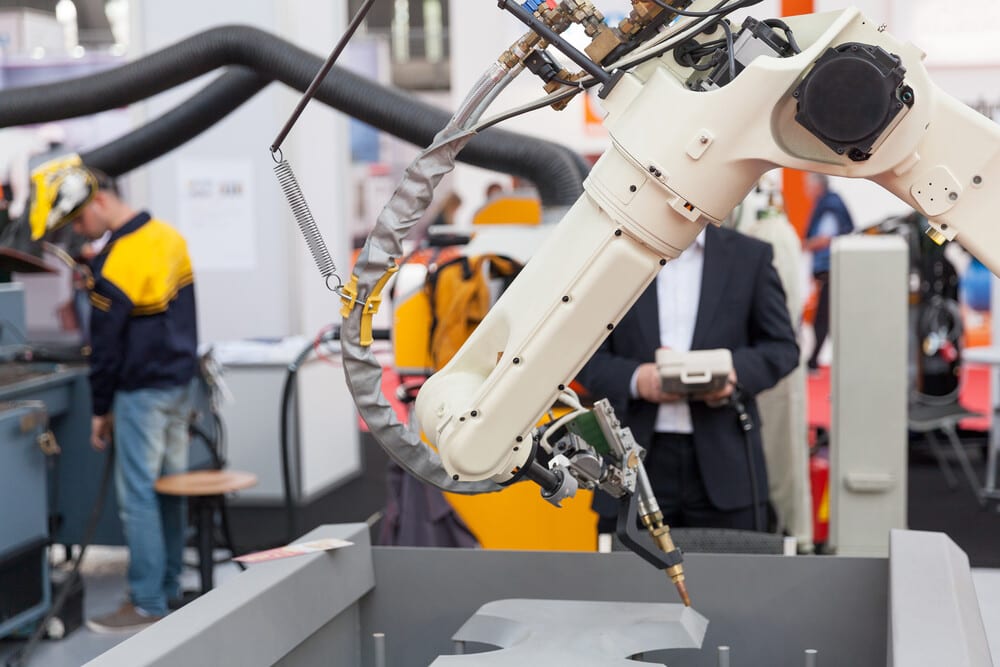

Automation has truly revolutionized the industrial workplace, increasing productivity, cost efficiency, and employee safety. And behind every adept robot or otherwise automatized mechanism, there are reliable connectors facilitating communication and connections within the industrial environment. They often must maintain their connections despite persistent environmental and mechanical stressors, such as fluctuations in temperature and sudden vibrations.

Automation connectors play an important role in a variety of applications, including factory-floor environments, electrical power generation/distribution, machinery, mining, geophysical exploration, farming equipment, and more. Input/output, power, and signal connectors are all needed in a variety of styles: circular, rectangular, panel-mounted, board-to-board, mezzanine, and even coaxial RF connectors. Most industrial interconnects rely on copper conductors, but some markets (such as factory automation networks and big data centers) have begun to turn to optical fiber due to its high bandwidth and resistance to electromagnetic interference (EMI).

The number of connector suppliers in automation has swelled over the years and this long-term trend is expected to continue growing in the years to come, especially as new applications arise and innovative technologies emerge.

Automation Connectors

Automation connectors tend to fit into one of two categories: (1) circular and rectangular connectors that follow military specifications and (2) commercial-grade connectors adapted to industrial environments. While connectors that confirm with MIL specs are intrinsically resistant to mechanical damage, commercial-grade connectors often need added seals, enhanced contact design, and more resilient materials to withstand the challenges presented by rugged industrial applications. In harsh, heavy-duty manufacturing environments, environmentally sealed connectors are consistently in demand.

Manufacturers are always looking to increase productivity and maintain employee safety, but they’re also increasingly concerned about embracing sustainability and promoting social responsibility. High-quality, reliable automation connectors are continually in demand, as they reduce downtime by including quick disconnect features and preventing the requirement to replace mechanical limit switches.

The Industrial Automation Industry

The industrial automation industry is moving toward, and in some cases requiring, machined processes. With machines doing the work, ingress protection (IP) is becoming increasingly important because grease, oil, and cutting fluids are present near where connectors may be in use. In addition, power connectors are used in the systems operating the machines.

A proud partner of the industrial automation industry, Positronic designed its Power Connection System series (especially the PLC series) to provide efficient power and high reliability. These connectors are a great fit for the industrial automation industry. They last a long time in the field, which is important when you’re operating 24/7 and/or need to keep up with customer demand.

What to Look for in Automation Connectors

Automation connectors are available in a wide range of shapes and sizes. Depending on your application and region, you may need to find connectors that abide by a particular set of standards or regulations.

What else should you consider when evaluating connectivity products for manufacturing operations?

- Rugged Design: In harsh and potentially damaging manufacturing environments, it’s often important to seek out connectivity products that are rugged, robust, and engineered to stand up to present and anticipated hazards.

- Easy Installation: Look for connectors that are constructed for fast insertion and easy installation.

- Reliable Power: Your automation connectors should offer excellent signal and power performance regardless of the environment and eliminate intermittent signals.

- Small Size: For some applications, a small sized connector is preferred to save space.

- Communication Capabilities: If you’ll be using a number of industrial protocols for process control in a critical manufacturing environment, look for automation connectors that can reliably communicate across a multitude of protocols.

Choose your connectivity solutions carefully to ensure that your automation system meets all of your enthusiastic goals and stringent guidelines for production, efficiency, safety, and quality. Not only will this help you produce better products and deliver those products to your customers more quickly, but also you’ll be able to set more competitive prices.

_____

The Internet of Things now plays a significant role in the industrial workplace and factory automation, and this trend is expected to continue going forward. As automation flourishes and more factories transform into smart factories, automation connectors will carry on as integral components of these systems, reliably supporting robotics and improving efficiency and safety.

If you’re looking for high-quality and highly reliable power and signal connectors, you can rely on Positronic. We believe it is our duty to provide our customers with certainty, and so we engineer products with exceptional performance levels to ensure our customers’ confidence and unerring trust. We partner with companies in a wide variety of global industries, and our substantial product portfolio with convenient navigation options makes it easy to find a product that fits your application. If you would like to request product recommendations, locate a sales agent, ask a technical question, or simply request a quote, please contact Positronic today.

Latest Posts

- A Series Backshell Product Derivative: Introducing Precision Machined Banded Backshells March 12, 2024

- Exploring the E-Mobility Market with Positronic Connectors December 1, 2023

- Positronic Announces EL Series Aluminum Backshells August 7, 2023

- Positronic Releases New Zinc Die-Cast Backshell Series July 26, 2023

- Why Are Semiconductors So Vulnerable to Supply Chain Shortages? July 7, 2023