Medical Connectors

Overview

When lives are on the line, healthcare workers rely on dependable, high-quality medical equipment. The right medical connectors can increase safety, efficiency, reliability, and ease-of-use in high-stakes environments like hospitals and clinics. Medical connectors are designed to the highest standards of quality to ensure the safety of patients and medical personnel, allowing healthcare professionals to focus on patient care instead of equipment management.

MEDICAL CONNECTORS DEFINED

Medical connectors provide interconnect solutions for a variety of healthcare devices in surgical, diagnostic, and therapy systems, amongst others. They’re regularly used by surgeons, physicians, nurses, radiologists, EMTs, and medical technicians, so reliability is essential. Many medical connectors feature smaller footprints to accommodate applications that require high power density in a small package. Other important features include durability, sterilization, and ease of use:

- Durability: Because medical connectors often require high numbers of mating cycles, they must be durable and sturdy. Some applications also necessitate the use of waterproof medical connectors that meet or exceed IP68 specifications.

- Sterilization: Medical equipment is subject to frequent sterilization procedures, so connectors must be corrosion-resistant and able to withstand repeated exposures to high temperatures and harsh cleaning conditions while remaining safe and hygienic.

- Ease of Use: Because medical connectors may be connected and disconnected by both trained professionals and untrained novices, they must be foolproof to prevent incorrect mating or damage to equipment.

USES

USES

Medical connectors are used in a variety of healthcare equipment, including MRI and CT scanners, ultrasound machines, EKG machines, exoskeletons, heart-lung support systems, wearable devices, defibrillators, ventilators, respirators, breathing machines, and other patient monitoring devices. From diagnostic devices and surgical instruments to therapy applications, dental applications, and cardiac assist devices, many applications within the healthcare industry require connectors.

Some applications mandate certain connector requirements. For example, respiratory monitoring devices in patient rooms may require screw-in connectors as opposed to push-pull to ensure a secure connection. Dental applications may require connectors with outstanding moisture resistance, ergonomic performance, and cable management. And due to the increasing demand for mobile medical devices, lightweight medical connectors with a small footprint are often required.

PRODUCTS

Do your medical devices require interconnect solutions that provide high power density in a small package? Positronic delivers this combination with our medical connector designs, our wide variety of options, and our use of solid machined contacts.

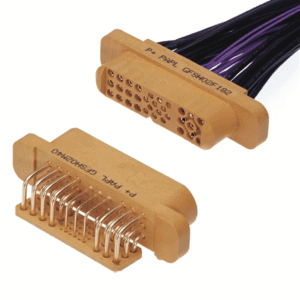

A selection of mixed-density power connectors, the GFSH Series is popular for medical applications. These products offer superior blind mating in a small package, and the multiple contact sizes available facilitate the mixing of AC/DC input, signal, and DC distributed output in a single package. Another option is the CBD Series, a part of the Combo-D family that offers mixed-density D-sub connectors – combining signal, power, coaxial, and high voltage contacts with fiber optic. This line offers fixed size 8 and 20 contacts and provides industrial performance. Another alternative for those seeking medical connectors, the SGM Series is part  of the Positronic mini-rectangular family of high-density connectors for rack and panel applications. These durable connectors feature straight solder terminations.

of the Positronic mini-rectangular family of high-density connectors for rack and panel applications. These durable connectors feature straight solder terminations.

Other Positronic series commonly used in medical devices include the following:

- Power Connection Systems (PLA) Series: These versatile, high-current, mixed-density connectors offer low-contact resistance and a discriminating locking system. These connectors have been used in a variety of medical applications, including neonatal intensive care incubators for premature or low-weight babies.

- Low-Profile Scorpion (LSP) Series: With their modular design and solid, machined contacts, the connectors in the LSP series allow for great flexibility and reduced cost. Despite their low profile, they provide high power density. They’re rugged, highly reliable, and economically priced.

- DD Series: Part of the high-density family of D-sub connectors, the DD series is designed for use in sheltered, mildly corrosive environments that experience a range of temperature, pressure, and humidity changes. The connectors use size 22, precision-machined contacts.

- Dual Port (DPA) Series: The DPA series is part of the dual-port, right-angle, D-sub family. These standard-density connectors are used to save panel and board space.

Positronic also produces custom connectors to help clients satisfy their applications’ specific requirements and unique goals.

Find Your Sales Agent

We cannot locate a sales agent for the country you selected.

Please view our global locations and contact the facility that is most geographically near you.