Connectors

Since 1966, Positronic has provided highly reliable and efficient connectivity solutions to customers around the world. Our catalog includes power, D-subminiature, circular, rectangular, and custom connector products and accessories, as well as value-added services. With their precision-machined contacts and mission-critical performance features, our connectors can meet industrial and military performance levels at various price points. From basic power supplies to advanced weapon systems, Positronic connectors play integral roles in all areas of the electronics industry.

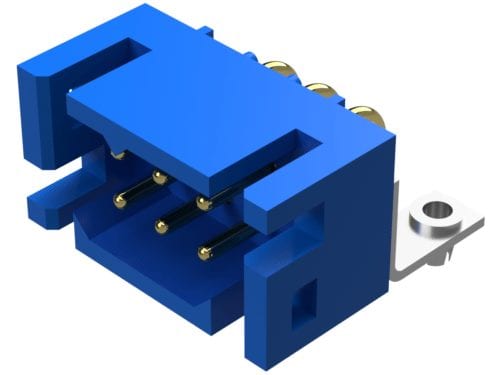

Our Power & Hybrid Connectors

All Positronic power connectors feature high power density and low contact resistance. Within our extensive catalog, you will find modular, blind-mate, waterproof, and touch-safe power connectors, ultra-high power interface connectors, and an innovative alternative to CT shorting blocks (the Autoshunt family). To design the ideal power connector for your application, check out the Scorpion series, which boasts the most versatile modular power/signal connectors on the planet.

- Scorpion

- SP Max

- Goldfish

- Dragonfly

- Power Connection System

- Great Golden

- Compact Power

- AdvancedTCA

- Infinity

- Safety Shroud

- Autoshunt

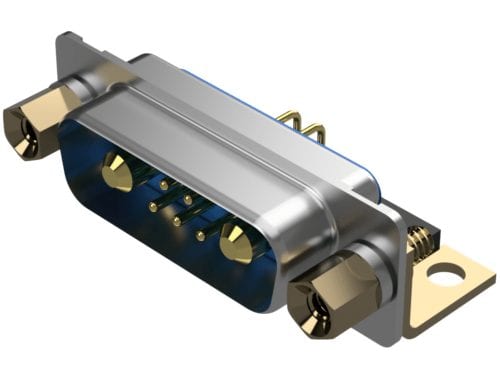

Our D-Subminiature Connectors

Positronic offers a variety of standard and high-density D-sub connectors and accessories, as well as ComboD-sub connectors. Highly reliable and available in numerous sizes and performance levels, Positronic D-subs use solid, machined contacts to ensure durability and strength. Explore our design features, including package size, contact, and mating variants.

- Mach-D

- Standard Density

- High Density

- Combo-D

- Waterproof

- Dual Port (Stacked)

- Adapter/Saver

- Hermetic

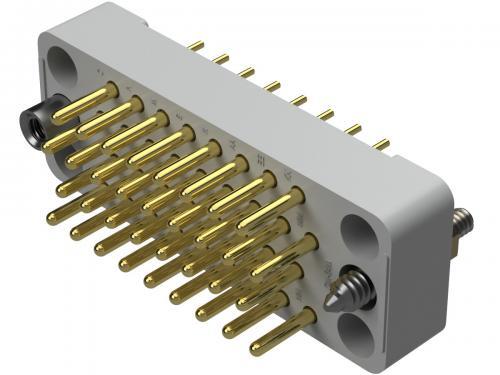

Our Rectangular Connectors

Looking for robust connectors for rack-and-panel applications? What about high-density connectors suitable for rack-and-panel or board-to-board applications? Or perhaps you simply need a low-profile, stackable power connector? Positronic has you covered with our selection of rectangular connectors.

- Rugged Rack & Panel

- Mini-Rectangular

- Slim Power

Our Circular Connectors

Positronic provides a variety of circular connectors, including high-reliability aluminum connectors for mission-critical applications, economical plastic signal connectors, high-performance composite connectors, and hex connectors for legacy avionics applications.

- Talon Mini

- Baby King Cobra

- Front Runner

- Circle Hex

Quality and Efficiency Through Vertical Integration

To ensure premium quality, reliability, and consistency, Positronic uses vertical integration. Each department plays a vital role in the development of our connectivity solutions:

- Engineering: The Engineering department designs new standard and custom products, modifies existing products to meet clients’ requirements, tackles value engineering initiatives, and offers technical support.

- Tooling: Using powerful tools like CNCs and EDMs, the Tooling department manufactures a variety of tools for in-house use (punch press dies, molds, assembly fixtures, cams, etc.) as well as assembly tools for customers around the globe.

- Metal Fabrication & Stamping: The Metal Fab department manufactures connector shells, backshells, angle brackets, cable clamps, and many metal accessories with its collection of punch presses.

- Test Laboratory: The Positronic Test Lab is certified to conduct a variety of tests to IEC standards, as well as QPL testing to military standards MIL-DTL-24308, SAE AS39029, and MIL-DTL-28748. It can also verify product performance to IP65 and IP67 requirements and has been approved by UL as part of the Client Test Data program.

- Molding: Using several thermoplastic and thermoset plastic molding machines, the Molding department forms insulators, backshells, angle brackets, cable clamps, and other plastic accessories.

- Machining: Renowned for its screw machine technology, Positronic boasts over 200 automatic lathes. Our Machining department manufactures thousands of varieties of electrical contacts as well as certain types of component hardware.

- Plating: The internal plating shop applies gold, nickel, copper, zinc, tin, chromate conversion, electroless nickel, and anodic coatings to connector components prior to assembly. Using inspection technology, the Plating department verifies that plating thickness, adhesion, and appearance meet military specifications.

- Manufacturing Engineering: Our Manufacturing Engineering department designs and executes state-of-the-art manufacturing process and proprietary equipment for in-house use, including high-speed automation assembly tools and robotic equipment.

- Assembly: Our Assembly department manages finished connector assembly as well as a variety of secondary manufacturing operations, including slotting, drilling, tapping, milling, depressing, sleeving, striping, and reeling.

- Quality Assurance (QA): Our QA department implements continuous improvement strategies and rigid process control to ensure consistently high quality. Positronic is AS9100/ISO9001 compliant at various locations and acts as a Designated Supplier Quality Representative (DSQR) for several renowned global companies.

- Sales & Customer Service: With key regional offices in the USA, France, India, Singapore, and China, our extensive sales and support network works with customers around the world. We also partner with several electronics distributors to ensure the delivery of superior service on a global scale.

If you’re interested in purchasing high-quality, durable connectors, check out the wide range of standard and custom products at Positronic. From D-subs and blind-mate connectors to cable assemblies and power connectors, we have it all. To get started, please fill out our contact form online and we will respond as quickly as possible.