Aerospace Connectors

Overview

Aerospace applications require rugged, reliable connectors. After all, in some cases, aerospace connectors are literally shooting for the moon. To operate and survive in harsh environments, aviation and space flight technologies demand lightweight, high-density connectivity solutions that can withstand extreme heat, shock, and vibration. Safety, reliability, and longevity are paramount.

AEROSPACE CONNECTORS DEFINED

The end-user customers in the aerospace industry have zero patience for inferior-quality interconnects that can adversely impact their equipment’s lifespan and performance. They seek out aerospace connectors that are optimized for high performance as well as size, weight, and power (commonly known as SWaP). Connectors deployed in aerospace applications must meet stringent requirements related to size, shape, reliability, and protection. In addition, due to the high-speed data rate used by today’s complex aeronautic equipment, many applications require interconnect solutions that support a high flow of information at accelerated speeds.

Due to the limited space on board aircraft and satellites, compact and space-efficient connectors are preferable. However, these connectors must also be lightweight; the higher the mass of the aircraft, the more energy is required to move it. Because lightweight materials like plastic and elastomers sometimes present outgassing issues over time, space-grade connectors must meet stringent outgas testing requirements. To qualify for aerospace deployment, they must meet a number of other performance metrics as well, such as the Electronic Components Industry Association’s EIA-364. In addition, they must be tested and approved by the space agency of the country they will be representing, such as the National Aeronautics and Space Administration (NASA) or the European Space Agency.

Numerous aspects of aerospace interconnects can be ruggedized to ensure hermetic sealing, robust resistance to shock, and superior strength to withstand vibration. These connectors are designed and developed for harsh environments and must be able to resist high temperatures, corrosion, electromagnetic interference (EMI), and lighting. Keep in mind that because connectors are typically located deep inside an aircraft, inside the wiring systems within the body of the structure, they are often difficult to access and replace. This is yet another reason why it’s important for aerospace connectors to be durable, resilient, and long lasting.

Numerous aspects of aerospace interconnects can be ruggedized to ensure hermetic sealing, robust resistance to shock, and superior strength to withstand vibration. These connectors are designed and developed for harsh environments and must be able to resist high temperatures, corrosion, electromagnetic interference (EMI), and lighting. Keep in mind that because connectors are typically located deep inside an aircraft, inside the wiring systems within the body of the structure, they are often difficult to access and replace. This is yet another reason why it’s important for aerospace connectors to be durable, resilient, and long lasting.

Each component of an aircraft plays a critical role – if it didn’t, it wouldn’t be included. While redundant systems are often added to aircraft and pilots can work around some issues, a faulty connection caused by a poorly reporting instrument will not be tolerated. Picture an aerospace connector that is located on the instrument panel of the cockpit. Any issues with that tiny connector could cause highly stressful issues that threaten the safety of the system. Hundreds of connectors are required to satisfy interconnect requirements aboard an aircraft, and each connector must work reliably to ensure a smooth operation.

USES

Interconnects for the aerospace industry are utilized in a variety of applications. These include communication and navigation equipment, in-flight entertainment systems aboard commercial aircraft, radar systems, guidance control, and others. Failure is not an option in these high-stakes applications, so aerospace connectors are held to the highest standards and specifications. Failsafe performance is a minimum requirement.

Aerospace connectors are suitable for use in any application requiring high-performance, non-outgassing, and low-magnetic characteristics. Whether they’re used in cockpit avionics or critical space-bound aircraft, aerospace connectors must perform in wide-ranging conditions and adverse environments.

PRODUCTS

PRODUCTS

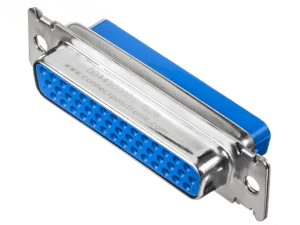

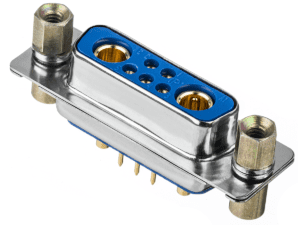

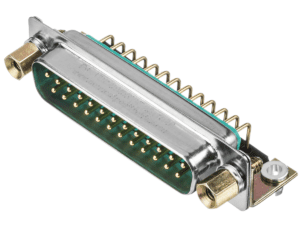

If you’re seeking top-of-the-line aerospace connectors, Positronic has you covered. We are a respected supplier of high-performance connectors that meet the stringent qualifications required for space flight, including the Goddard Space Flight Center S-311 and MIL-DTL-24308 Class M specifications. Our D-subminiature connectors work well in many aviation and space flight applications. Some of our top choices include the following:

- HDC Series: The HDC series of standard-density D-sub connectors consists of size 20, fixed, machined contacts with military/aerospace performance features and an operating temperature of -55°C to 125°C.

- DD Series: The DD series of high-density D-sub connectors consists of size 22 machined contacts with military/aerospace performance features and the option for wire, right-angle solder, or straight solder terminations.

- RD Series: The RD series of standard-density D-sub connectors consists of size 20, machined, removable contacts with military/aerospace performance features, and an operating temperature of -55°C to 125°C.

- CBD Series: The CBD series of combo-D, mixed-density D-sub connectors mixes signal, power, coaxial, high-voltage, and fiber optic interconnects. It includes fixed size 8 and size 20 contacts and industrial performance features.

- CBDD Series: The CBDD series of combo-D, mixed-density D-sub connectors mixes signal, power, coaxial, high-voltage, and fiber optic interconnects. It includes size 8 and size 20 contacts and military/aerospace performance features.

Find Your Sales Agent

We cannot locate a sales agent for the country you selected.

Please view our global locations and contact the facility that is most geographically near you.

PRODUCTS

PRODUCTS