PosiBlog

When Failure is Not an Option: The Rigor of Mil-Aero Specs

by Mark Sample, Director of Quality, Positronic

Put yourself in these situations:

- Your F-16 is loaded with armaments, tracking the movement of a terrorist caravan on a dusty mid-eastern desert road. The security of an entire province depends on the success of your mission.

- Your aircraft carrier is weaving through the same waters you’ve been traversing for the last six months, establishing a safe haven and platform for military response in a troubled region.

The space probe you’re tracking is nearing Saturn, 746 million miles away, where the dreams of a 13 year-long project will be fulfilled. If … all the systems continue to perform to spec, and they survive the rigorous flyby and negative 185 degrees Celsius.

The space probe you’re tracking is nearing Saturn, 746 million miles away, where the dreams of a 13 year-long project will be fulfilled. If … all the systems continue to perform to spec, and they survive the rigorous flyby and negative 185 degrees Celsius.

What do these three scenarios have in common? They are environments in which failure is not an option, where failsafe performance is the minimum requirement. For this reason, the suppliers of components used to build and operate military and space instruments are held to standards and specifications that are the highest in the world.

These standards are commonly known as mil-spec or mil-aero specs. They comprise the gauntlet faced by electrical connector manufacturers who dare to venture into this world of extreme benchmarks.

Let’s look at the industries that demand this rigorous performance by their connectors.

Military

Befitting the military’s high standards, military connectors are durable and highly reliable products designed to fit the demands of the armed forces. Utilized in a variety of applications, they come in many shapes and sizes and can be found everywhere from communications offices to war fronts and naval ships.

Military connectors were developed in the 1930s for severe aeronautical and tactical service applications. Through the years, connectors have become smaller and lighter, increased their bandwidth and security, and reduced energy consumption. They have also become durable enough to endure sizzling heat, blustery winds, and even flash floods.

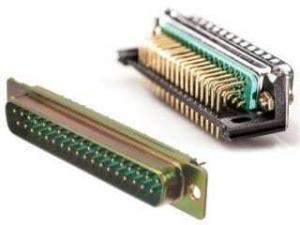

Positronic in the Military: Positronic offers a wide range of military connectors. The most popular of these is the D-Subminiature product line, with its mil-spec versions sold under the part prefix “M24308”. Another popular mil-spec connector from Positronic is the Rectangular Rack & Panel product. The solid machined size 16 contacts offer high reliability power connector with mil-spec capability.

Aerospace

Space connectors are not only efficient at their job; they must also be capable of standing up to harsh environmental conditions, and long lasting (because repair is typically impossible once you’ve left the earth’s surface).

Space connectors are used in electronic equipment in space applications, whether on a spacecraft or a satellite. To qualify for this elite task, the connectors must be tested and approved by NASA or the European Space Agency (or the space agency of whatever country they will be representing).

Due to their unique mission, space connectors must be compact, because there is only so much room on a space vehicle. Weight is another major consideration since the cost of launching a payload into space is directly related to its weight of that payload. The connectors must also be extremely reliable, and they must be able to withstand severe environmental conditions like shock, extreme temperatures and vibration.

Three major categories of connectors are used in space flight application: D-subminiature, micro-miniature and circular.

Positronic in Space: Positronic is a respected supplier of high performance D-subminiature connectors that meet the stringent qualifications for use in space flight. Although they are qualified to the Goddard Space Flight Center S-311 and MIL-DTL-24308 Class M specifications, these space connectors are suitable for use in any application requiring high performance, non-outgassing and low magnetic characteristics. Offered in a broad range of termination styles, contact variants, and with many available accessories (including lightweight aluminum hoods/backshells), these connectors are highly reliable.

The Mil-Aero Gauntlet of Standards

The military and aerospace markets encompass a wide variety of different applications, including: radar, cameras, vehicular electronics, avionics, embedded systems, UAVs, and many others. Connectivity is at core of all the applications within these markets, to ensure peak performance and reliable data transmission. As such, these applications require high-performance and high-reliability components built to military or aeronautics standards.

These standards include the following.

- Ability to withstand external environment extremes in temperature, pressure, and moisture.

- Select connector housing materials with the right impact on electrical and mechanical performance.

- Harmonize the connector specifications with the application environment and required performance, to avoid the selection or creation of an under- or over-qualified connector product.

- Choose customized connectors when necessary to address severe size constraints and integration of a connector into a system.

- Harsh-environment connectors need to be designed to ensure optimal performance in their difficult workspace.

All of this is in the Positronic wheelhouse. Driven by its mantra, the science of certainty, extraordinary standards of the mil-aero world are the everyday work of Positronic.

Latest Posts

- Milexia and Neumueller Named as Exclusive Value-Add Distributor Partners for UVAC Hermetic Feedthrough Flange System March 26, 2025

- Powering the Future of eVTOL Aircraft Travel January 24, 2025

- MACH-D Connectors: Highly Reliable & Customizable August 29, 2024

- Combo-D Connectors from Positronic: Compact Power and Precision May 1, 2024

- A Series Backshell Product Derivative: Introducing Precision Machined Banded Backshells March 12, 2024